You must have come across sports news and entertainment reports related to older people receiving national and/or international awards in the world of fitness, sports and exercise at the age of between 70s to 90s. This ain’t a fantasy world, but adaptation of an exceptional thinking process that each people can stay fit, healthy and enjoy the nature’s given beneficial fruits till the end of their beautiful life. To raise the bar, Tradeindia presents Outdoor Playground Equipment manufacturers, suppliers and dealers in India.

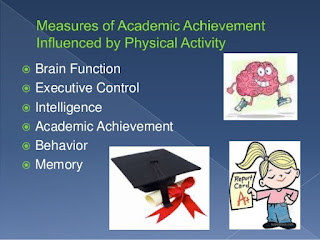

A playground is a play area designed keeping in mind the targeted age group. There are playground equipment for children (including kindergarten), adults, older people and people with disabilities. Many studies show that actively participating in outdoor physical activities lead to excellent brain functioning, good body and mind control and coordination, and enhanced memory.

10 Must-Have Outdoor Playground Equipment for Children

Children’s specialists and fitness trainers agree that an hour of physical fitness activity is vital for children’s healthy body and fresh mind. Kids require physical coordination, flexibility, strength and recreation that also aid in mental and emotional development. All these result in confidence, positive attitude and smart personality – a basic stage to prepare kids for schooling and high-school education for which you must go through the list of 10 must-have Outdoor Playground Equipment for kids:

1. Seesaw

2. Merry-go-round

3. Slide

4. Jungle gym

5. Swing-sets

6. Chin-up bars

7. Playhouses

8. Mazes

9. Playground climbers

10. Spring riders

Best Outdoor Playground Equipment for Adults

Playgrounds aren’t for children anymore. In this digital world, grown-ups too require to do physical activities to get rid of obesity and other life-threatening mild-to-severe medical conditions. There are specific playgrounds for adults which have facilities for physical activities and playing informal sports such as: |

1. Running track

2. Basketball court

3. Baseball

4. Chin-up bars

5. Skating arena

6. Tether ball

7. Bike Rack – Cycling track

Outdoor Playground Equipment for Seniior Citizens

To make our world more age-friendly, the inclusion of older people in community is a necessary step. This enables all age-group people to actively participate in community tasks. Nowadays, outdoor playgrounds are designed in a way that enable older people to do some exercises, jogging and help in public engagement to avoid unhealthy body and mental diseases caused by lack of physical activity and general interaction. Some elderly playground equipment includes:

1. Hip spring: Improve body balance and control

2. Circular track: For coordination and balance

3. Shoulder arches: Shoulder and chest stretching devices

4. Balancing rail: Intended for enhancement of core control and abdominal muscles

Benefits of Outdoor Playground Equipment

It is imperative for children and people of all ages to practice some physical activities for an hour every day to have a healthy state of body and mind, build fine motor skills, core strength, stability, control balance and coordination in order to stay fit throughout the long life.

Besides, in this world of digital mobilization, people are spending their valuable time performing digital activities most of the days where they tend to interact with life-threatening diseases (mild to severe) that could lead to bad-health body and anxious mind. Physically interacting with people relieve pain and stress that can produce a feeling europhia – an indeed feeling to enhance mental and emotional stability.

Having such Tradeindia’s offered Outdoor Playground Equipment which do not consider any age limitations can help people personally, as well as, lead businesses to a booming stage as this is the time to leave this prejudiced system behind and grow naturally with positive impact on the lives of people.